How a Portable Toilet is Made: An In-depth Look

Portable toilets, often seen at events or construction sites, are essential for providing sanitation solutions where traditional restrooms are unavailable. But have you ever wondered how these mobile restrooms are made? Let’s dive into the fascinating process!

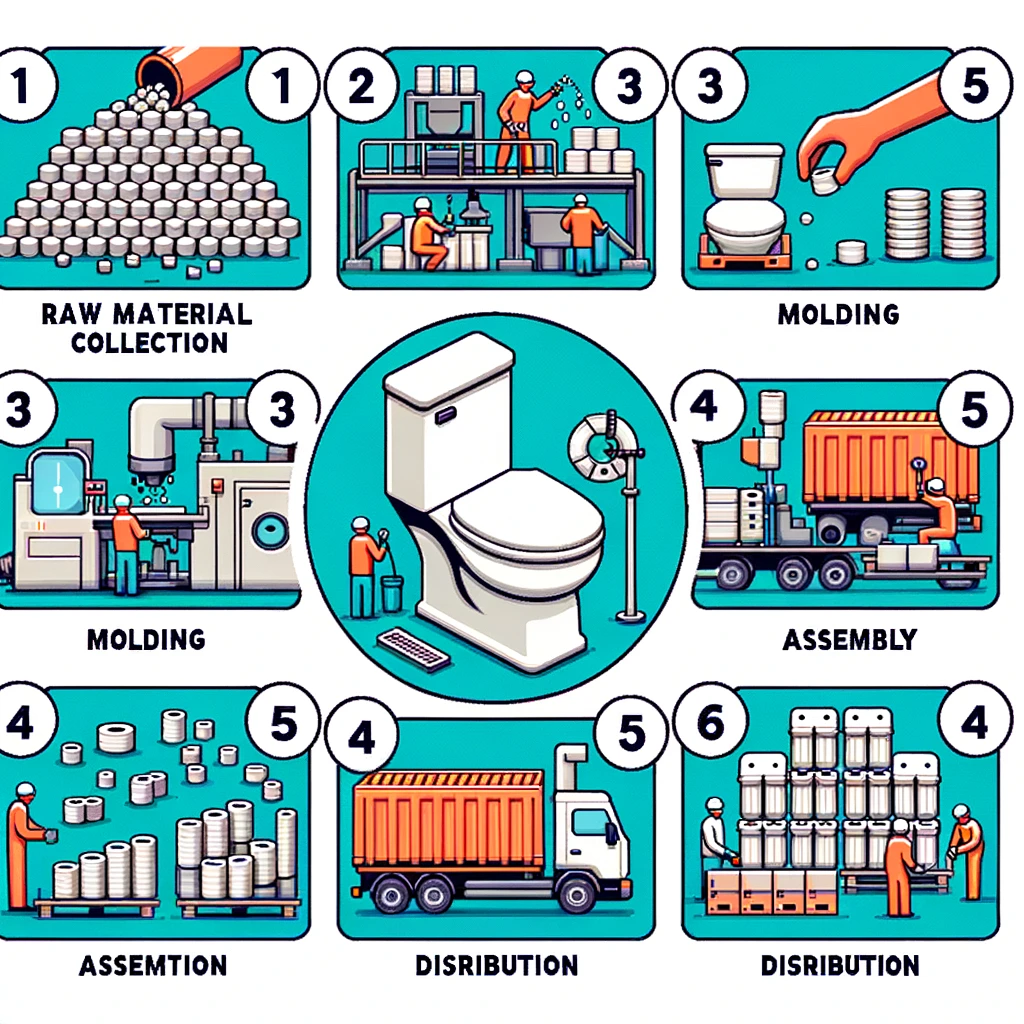

Step 1: Raw Material Sourcing

The primary material used in the manufacturing of portable toilets is High-Density Polyethylene (HDPE). This robust and durable material ensures the longevity of the toilet, even under extreme conditions.

Step 2: Molding Process

Once the HDPE is sourced, it’s transformed into various components of the toilet. This is done through an injection molding process where the plastic is melted and injected into molds to form the base, walls, roof, and other parts.

Step 3: Assembly

After molding, the various parts are assembled. Skilled workers fit the components together, secure the roof, attach the door, and ensure everything aligns perfectly. Every piece is designed to fit seamlessly, preventing any leaks or mishaps.

Step 4: Quality Control and Testing

Quality is paramount! Once the assembly is complete, each portable toilet undergoes rigorous quality checks and testing. This ensures that there are no defects and that the unit is water-tight. After all, a leaky portable toilet is no one’s friend!

Step 5: Ready for Shipment

The final step is shipment. Portable toilets are stacked efficiently on trucks, ready to be delivered to events, construction sites, or wherever they’re needed.

The creation of a portable toilet is a blend of modern technology and skilled craftsmanship. The next time you see one at an event or a construction site, you’ll have a newfound appreciation for the effort and detail that goes into its making!

Real-life Example:

Did you know that companies like Midland Toilet Hire not only supply portable toilets to events and construction projects but also provide effluent emptying services? So, they play a significant role in both the provision and maintenance of these essential facilities.

Quick Facts:

Material Used: High-Density Polyethylene (HDPE)

Primary Use: Events, Construction Sites, and Outdoor Gatherings

Benefits: Mobility, Durability, and Cost-Effective

I hope this article sheds some light on the intricate process of making portable toilets! If you’re organising an event or managing a construction project, consider hiring portable toilets from reputable suppliers to ensure sanitation needs are met seamlessly.